Contact Information

Contact personManager Li

Tel:86-0574-87628288

Fax:86-0574-87565018

Mobile phone:86-13967883478

Email:ligq@veekim.com.cn

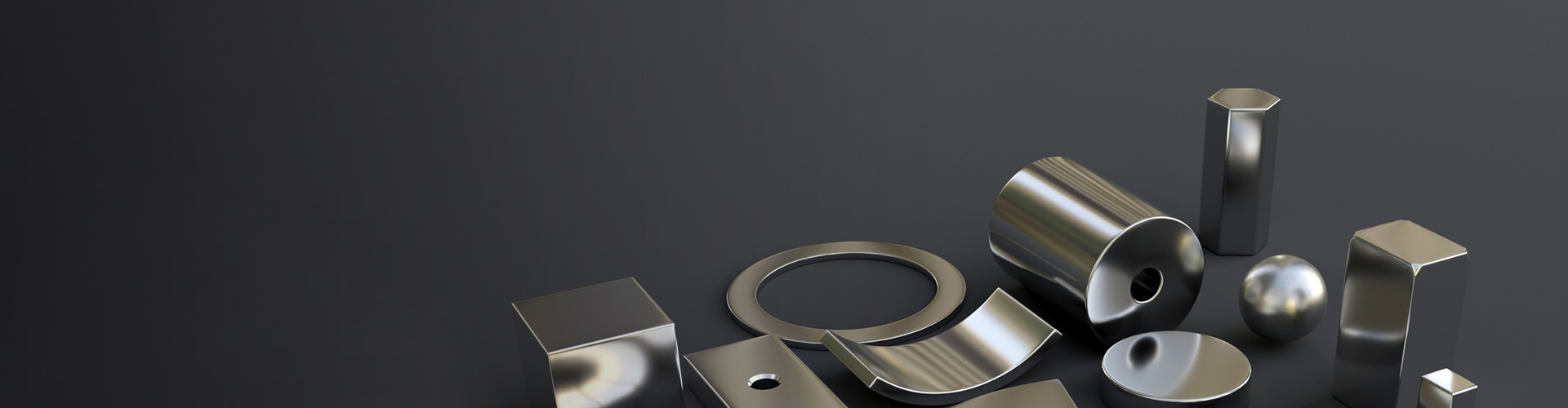

Hard ferrite

Ceramic magnets, also known as hard ferrites, are composed of strontium carbonate and iron oxide. They are widely used in motors, speakers, toys, and other applications due to their excellent demagnetization resistance and cost-effectiveness.

Ferrite magnets are manufactured using sintering and injection molding processes. Although the molds used for injection molding are extremely expensive, they allow for the production of parts with complex shapes and tight tolerances.

Although hard ferrite magnets have relatively poor thermal stability, they can still be used in environments up to 300°C. Due to their hardness and brittleness, they are typically cut and ground only using diamond wheels. Additionally, ferrites exhibit excellent resistance to rusting, eliminating the need for surface treatments.

After blending the raw materials and turning them into granules, the mixture undergoes calcination (pre-sintering), passing through several intermediate stages to ultimately yield the barium ferrite phase (BaFe12O19 or SrFe12O19).

After grinding the pre-sintered particles into a powder, the material is then wet- or dry-pressed to form a magnetic structure—either non-isotropic (anisotropic) or isotropic—and subsequently sintered. The resulting hard ferrite ceramic exhibits the typical mechanical hardness and brittleness of ceramics, making it commonly processed by grinding with diamond circular saw blades.

Product images are being updated...