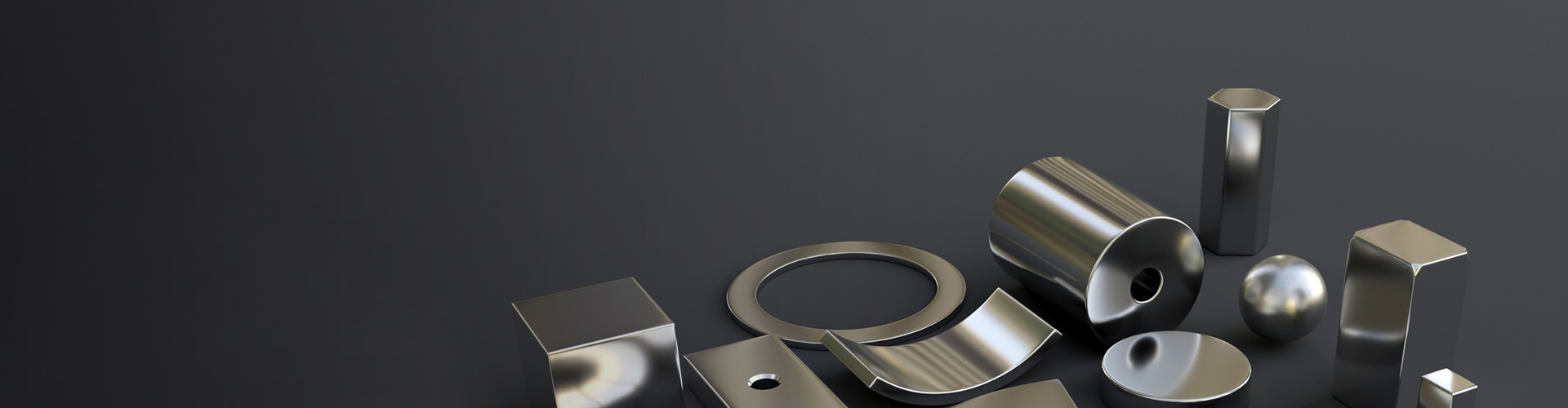

Veekim 0014 free-bonded neodymium-iron-boron is a composite-type neodymium-iron-boron permanent magnet created by uniformly mixing neodymium-iron-boron powder with binders such as resin, plastic, or low-melting-point metals, followed by processes like compression, extrusion, or injection molding.

Jet molding is effective for producing products with complex shapes and thin walls.

The compression molding method is limited to magnets with simple geometric shapes, but it achieves relatively high density and produces magnets with a stronger magnetic field compared to injection-molded ones.

Bonded neodymium-iron-boron magnets have lower magnetic properties compared to sintered neodymium-iron-boron magnets, but they can be manufactured into high-precision, complex-shaped magnetic components.

Generally, bonded neodymium magnets do not require final finishing (machining or trimming). To prevent rusting, the magnet surfaces are typically coated with epoxy or nickel plating.

Bonded neodymium iron boron is made by mixing rapidly quenched neodymium iron boron powder with a polymer binder.

Weijing is capable of producing several bonded neodymium-iron-boron models.

Compression Molding

First, mix the neodymium-iron-boron powder with the epoxy material, then place the mixture into a mold and press it into shape.

Neodymium-iron-boron magnets with a remanence (Br) ranging from 300 to 830 mT can be produced. By applying an electroplating process to the magnet's surface, it becomes smooth and gains superior durability characteristics.

Injection Molding

This method is particularly well-suited for high-volume production. Although the remanence is lower compared to compression-molded magnets—ranging from approximately 200 to 630 mT due to the relatively lower NdFeB powder content—it allows for the creation of magnets in virtually any shape. This material can also be used for coating applications (e.g., directly injecting adhesive material onto the surface of a shaft), making these magnets an ideal replacement for ferrite magnet tiles in brushless motors.

Coating

By using the injection molding process, we can seamlessly integrate magnetic materials and/or plastic technologies into the molding process. This allows magnets to be precisely embedded alongside shafts, washers, and other functional components—making it an attractive solution for high-volume production of insert parts such as shafts, washers, and more. With fully automated facilities located in Japan, China, and Thailand, we’re able to deliver products of exceptional quality at highly competitive prices.

Multi-component injection molding

Multi-component injection molding allows different plastic materials with varying properties to be safely joined together using a single injection molding process.

The advantage of this method is:

High precision— all components are produced using the same manufacturing process.

Choosing to combine different functions within the same component

Shapes are virtually limitless, including miniaturization.

Better adhesive properties, as the various components bond together.

Fewer manufacturing steps

Reduce processing costs

Significantly reduce manufacturing costs for large-scale, complex components